Abrasives

Abrasives allow you to finish items you have been working on, with many different types available to help you complete the best finish for your products. We have a phenomenal selection of abrasive products available here at Fosseway Tapes including sand paper and sander machines. Our range contains the most renowned brands including Mirka and 3M, so you can expect outstanding performance and quality with all of our products.

Showing all 38 resultsSorted by popularity

-

Sanding Dust Extractors

-

Sand Paper

-

Sander Machines

-

Sanding Discs

-

Sanding Pads

-

Sanding Rolls

-

Mirka Carat Flex Abrasive Roll 115mm x 50m | Stearate Coated, Flexible Latex Paper for Fine Finish Sanding, Wood, Lacquers & Profile Sanding

From: £31.46 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Foam Sanding Block 100x70x28mm Various Grits | Durable, Flexible Sponge for Wet/Dry Sanding of Wood, Paint, Plaster & Automotive Finishes

£0.99 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Mirlon® Various Colours Finishing Abrasive Pads 152x229mm (P320 Grit) | Flexible Non-Woven Scuff Pad for Automotive, Wood & Metal Surface Prep

£1.03 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Avomax Abrasive Roll 115mm x 50m (Various Grits) Aluminium Oxide Sandpaper Roll for Wood, Paint & Filler, Strong Backing for Hand or Machine Sanding

From: £28.49 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka 1230 Dust Extraction Vacuum Bags 5 Pack – 30L Capacity, High Filtration, Clean Disposal, Compatible with Mirka 1230 Dust Extractors

£42.78 Inc. VAT Add to basket -

Mirka Hiomant Roll Various Grits (115mm x 50m) | Durable Aluminium Oxide Sandpaper for General Purpose Hand & Light Machine Sanding on Wood & Paint

From: £29.99 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Dustbag Fleece for Extractor 1025 L (5 Pack) | 25 Litre Bags with Self-Sealing Mechanism for Efficient Dust-Free Sanding

£23.39 Inc. VAT Add to basket -

Mirka Abranet Various Grits Sanding Discs 225mm (25 Pack) | Dust-Free Mesh Abrasive, Hook & Loop, No Clogging, for Wood, Paint & Automotive

£40.80 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Carat Flex Abrasive Roll – 115mm x 5m (Various Grits) Flexible Silicon Carbide Sandpaper for Fine Finishing on Paint, Wood & Lacquer

£5.40 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Avomax Plus Sanding Roll 115mm x 5m (Various Grits) Durable Aluminium Oxide Abrasive for Wood & Paint, Long-Lasting Performance, Flexible Paper Backing

From: £3.99 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Trend Jointing Biscuits No 00/10/20 (1,000 Pack) | High-Quality Die-Cut Beechwood Jointing Biscuits for Strong & Accurate Furniture and Cabinet Making

From: £35.50 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Sanding Sponges 120x98x13mm Various Grits (100 Pack) | Waterproof, Flexible Dual-Sided Foam for Wood, Paint, MDF & Plaster Sanding

£64.00 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Abranet Sanding Strips 70mm x 125mm (50 Pack) | Dust-Free Mesh Abrasive for High-Performance Sanding on Wood, Primer & Composites

From: £19.69 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Hand Sanding Kit 70mm x 198mm – Ergonomic Sanding Block for Comfort & Control, Ideal for Large Areas & Detail Work, Lightweight & Durable

£39.60 Inc. VAT Add to basket -

Mirka Hiomant Abrasive Roll – 115mm x 10m (Various Grits) Yellow Aluminium Oxide Paper for General Purpose Sanding of Wood, Filler & Paint

From: £12.71 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka CEROS or ROS Random Orbital Sander Replacement 150mm Backing Pads 150mm 5/16″ Grip 51H Medium

£40.45 Inc. VAT Add to basket -

Mirka 150mm 67H Pad Saver | 5mm Thick Multi-interface Pad for Sanding Contours, Protects Backing Pad & Improves Dust Extraction

From: £7.06 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Abranet P80 Sanding Strips 70mm x 198mm (50 Pack) | Dust-Free Mesh Abrasive for Dry Sanding on Wood, Primer & Composites

£30.49 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Oakey Flexible Sanding Sponges (4 Pack) | Dual Grit 100g Fine/60g Coarse, Washable Foam Pads for Preparing Doors, Frames & Skirting Boards

£3.99 Inc. VAT Add to basket -

Mirka Dust Extractor Filter – Replacement Filter for DE 1230 & DE 1242 Models, High-Efficiency Filtration for Dust-Free Sanding, Easy to Install

£52.00 Inc. VAT Add to basket -

Black Mirka Dust Extractor Hose – Flexible Anti-Static Hose for Efficient Dust Removal, Compatible with Mirka Sanders & Extractors, Durable Build

£52.00 Inc. VAT Add to basket -

Mirka Mirlon® UF Finishing Roll 115mm x 10m Various Grits | Flexible Non-Woven Scuff Pad for Final Prep of Lacquer, Paint & Auto Body Finishes

£34.29 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Basecut Various Grits Sanding Discs 150mm (50 Pack) | 15H Aluminium Oxide, High-Efficiency Hook & Loop for Aggressive Stock Removal & Paint Stripping

£15.60 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka Dust Vacuum Bags (5 Pack) | Fleece Bags for Extractor Models 412, 415, 912 & 915 – Ideal for CEROS, DEROS & Abranet Dust-Free Sanding

£43.91 Inc. VAT Add to basket -

Mirka Hand Sanding Block 70mm x 125mm | Ergonomic, Dust-Free, Hook & Loop Tool for Abranet Strips & Grip Abrasives on Small Surfaces

£18.99 Inc. VAT Add to basket -

Mirka DEOS II 81x133mm 230V Deco Solution Kit | Low Profile Orbital Sander w/ Brushless Motor, Bluetooth, Case & Abranet Strips for Wood/Trim

£525.00 Inc. VAT Add to basket -

Mirka 1230 L PC Dust Extractor – 230V, Professional Cyclonic Vacuum with Auto Start & 4m Hose, Compatible with Mirka Sanders

£499.00 Inc. VAT Add to basket -

Mirka Roundy Kit KIT00ROUND – Ergonomic Hand Sanding Kit with 150mm Round Block & Abranet Discs, Ideal for Detail Work on Wood, Paint & Filler

£48.90 Inc. VAT Add to basket -

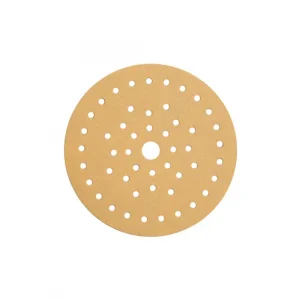

Mirka Gold Various Grits Grip Multifit Sanding Discs 150mm (100 Pack) | Aluminium Oxide, Anti-Clog, Multi Hole for Wood, Metal & Paint

From: £26.10 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka DEOS 383CV Electric Sander – 230V, 70mm x 198mm with Abranet ACE Pads, Low Profile Design for Precision Sanding & Dust-Free Performance

£510.00 Inc. VAT Add to basket -

Mirka DEROS II 350CV 77mm 230V Orbital Sander Solution Kit | 5mm Oscillation, Brushless Motor for Small Repairs & Kitchen Refurbishing

£479.00 Inc. VAT Add to basket -

Mirka HEPA Filter H13 for DE 1230 / DE 1242 Dust Extractor | Certified 99.97% Particulate Filtration for Safe, Clean & Dust-Free Sanding

£106.80 Inc. VAT Add to basket -

Mirka DEXOS 1230 M AFC Dust Extractor Kit | 30L M-Class Vacuum w/ Automatic Filter Cleaning & 4m Hose for Dust-Free Sanding & Industrial Use

£1,020.00 Inc. VAT Add to basket -

Norton Expert Rubber Sanding Block 102x67x29mm | Ergonomic Hand Tool for All Types of Sandpaper – Provides Even Abrasive Support

£4.99 Inc. VAT Add to basket -

Mirka Basecut Abrasive Roll Various Grits (115mm x 50m) | Economical Sandpaper for Paint Stripping, Wood, Lacquers & General Purpose Aggressive Sanding

From: £29.39 Inc. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Mirka DEROS RS 600 150mm Rotary Sander Solution Kit | Heavy-Duty, Low Profile Electric Sander for Paint Stripping & Coarse Grinding

£598.00 Inc. VAT Add to basket -

Mirka Net Backing Pad 125mm – Hook & Loop Backing Pad for Net Sanding Discs, Optimized for Dust Extraction, Durable & Flexible for Smooth Finish

£39.00 Inc. VAT Add to basket -

Mirka DEROS II 680CV 150mm Orbital Sander w/ 8.0mm Orbit | Low Vibration, Brushless Motor & Bluetooth for Automotive, Woodworking & Decorating

£580.00 Inc. VAT Add to basket

Abrasive Supplies

From sanding pads to sanding discs we have an extensive collection of products to meet all of your requirements. We have specially selected our stock to ensure that we provide the perfect solutions to all your sanding and finishing needs. Browse our abrasives in full now to take advantage of the amazing competitive prices on offer. Alternatively, if you require further information or have any questions regarding abrasive supplies, get in touch with us today to speak to our experts.

What are Abrasives?

Abrasives are a class of materials used to shape, polish, or finish other materials through rubbing or grinding. They come in a wide variety of shapes, sizes, and materials, and are used in a variety of industries, from metalworking to woodworking to electronics.

Most common types of abrasives

One of the most common types of abrasives is sandpaper, which is typically made by bonding grains of abrasive materials, such as aluminium oxide or silicon carbide, to a flexible paper or cloth backing. Sandpaper is used to smooth or remove material from a surface, such as sanding a piece of wood or metal.

Another common type of abrasive is grinding wheels, which are used in machining operations to remove material from a workpiece. Grinding wheels are typically made of a matrix of abrasive particles held together by a binder, such as resin or rubber. They come in a variety of shapes and sizes, and can be used for precision grinding or rough shaping of materials.

Industry uses

Abrasives are also used in the electronics industry, where they are used to shape or polish the surfaces of silicon wafers used in computer chips. In this application, extremely fine abrasives, such as colloidal silica or cerium oxide, are used to produce a highly polished surface that is free from defects or imperfections.

How to select the right abrasive?

When selecting an abrasive, it is important to consider factors such as the material being worked on, the desired level of finish, and the required precision. Coarser abrasives, such as sandpaper with a lower grit number, are used for rough shaping or removal of material, while finer abrasives, such as sandpaper with a higher grit number, are used for smoothing or polishing surfaces.

Backing material

In addition to the type and grit of the abrasive, it is important to consider the backing material and adhesive used to attach the abrasive to the backing. For example, a flexible cloth backing may be used for sandpaper used on curved surfaces, while a rigid plastic backing may be used for grinding wheels used in metalworking operations.

What are abrasives?

Abrasives are materials used for rubbing, grinding, or polishing other materials. They are used in a variety of industries to shape, smooth, or finish surfaces.

What are some common types of abrasives?

Some common types of abrasives include sandpaper, grinding wheels, diamond abrasives, and various other abrasive powders.

What are abrasives made of?

Abrasives can be made from a variety of materials, including aluminium oxide, silicon carbide, diamonds, and other minerals.

How are abrasives used?

Abrasives are used by rubbing, grinding, or polishing surfaces to achieve the desired level of smoothness or shape. They can be used on a variety of materials, including metal, wood, glass, and plastic.

What factors should I consider when selecting an abrasive?

When selecting an abrasive, you should consider factors such as the material being worked on, the desired level of finish, and the required precision. Coarser abrasives are used for rough shaping, while finer abrasives are used for smoothing or polishing surfaces. The backing material and adhesive used to attach the abrasive to the backing should also be considered.

How can I tell when an abrasive is worn out?

When an abrasive is worn out, it will no longer be effective at shaping, smoothing, or polishing the surface. Signs that an abrasive is worn out may include a dull appearance or a loss of effectiveness.

Are there any safety concerns associated with using abrasives?

Yes, there are safety concerns associated with using abrasives. Dust and debris generated by the use of abrasives can be harmful if inhaled, so it is important to wear appropriate safety gear, such as a dust mask and safety goggles. It is also important to follow proper safety procedures when using abrasives, such as securing the workpiece and ensuring that the abrasive is properly secured to the backing.